ABOUT GPTECH

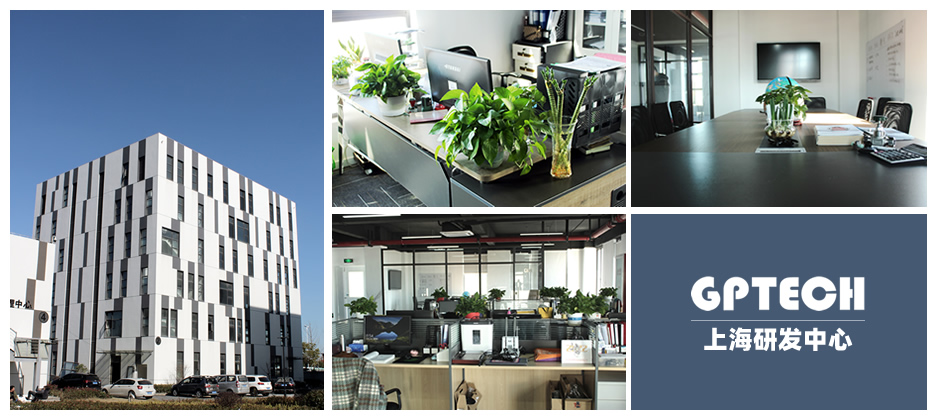

Jipai Fluid Control Technology (Shanghai) Co., Ltd. was established in Shanghai in 2014 with the introduction of technology management from the US headquarters. The company has a 3000 square meter sales, research and development, and production factory in Shanghai,

And in 2017, a 13000 square meter R&D and production factory was built in Taicang, Jiangsu, with one 1000 square meter CLASS1000 dust-free laboratory

And a 500 square meter CLASS100 clean room to meet the high cleanliness requirements of fluid control system products in the semiconductor and biopharmaceutical industries.

In 2023, the company will build a modern liquid cooling technology industrial base covering an area of 30000 square meters in Nanxun, Zhejiang,

Focusing on the research and manufacturing of liquid cooling systems, liquid cooling pipes, quick couplings, customized stainless steel integrated pipelines, and other products for data centers,

Further expand the application and influence in the field of new cooling technologies.

The company has more than 200 world-class precision CNC machining equipment, automatic welding equipment, and various customized assembly equipment and leak testing equipment,

Mainly engaged in the research and development of semiconductor high-purity gas control equipment, high-purity chemical transportation equipment, gas control valves, and pressure regulation products.

The products include: special gas cabinets, laboratory gas supply systems, bellows valves, sanitary diaphragm valves, sanitary ball valves, special alloy valves, pipe fittings, and special alloy valve products.

-

Industry application

Data center

Semiconductor industry

Prefabricated pipeline

Energy storage

High purity fluid application system

Special Alloy

-

Technical capabilities

Clean room production

welding technique

Surface treatment process

Documents and certificates

Engineering scheme design

-

Products

Liquid cooled products

Special alloy products

Semiconductor high-purity gas products

-

About us

Company Profile

Corporate culture

Responsibility and values

History and brand

R&D center

Innovation system

WeChat official account

COPYRIGHT © 2024 GPTECH ALL RIGHTS RESERVED